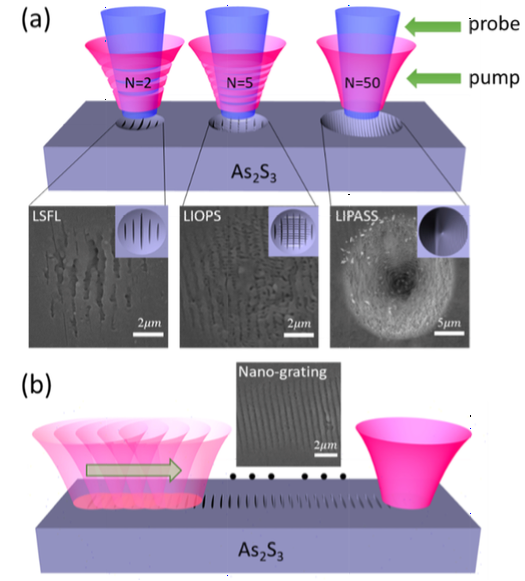

Laser-induced periodic surface structures (LIPSS) are a universal phenomenon that can allow tailoring nanoelectronics and nanophotonics devices. However, there is an issue about the formation mechanism of LIPSS, and the current research mainly focuses on the formation process of the individual structures, such as the low spatial frequency LIPSS (LSFL), sub-wavelength structures, and laser-induced periodic annular surface structures (LIPASS). A whole process formation picture of the series of these periodic structures is still missing. In this study, a pump-probing setup is applied to ensure the real-time and in situ monitoring of surface modification under different pulse numbers. LSFL firstly appears on the surface after two laser shots, and then, laser-induced orthogonal periodic structures (LIOPS) become the dominant morphology after five laser shots, which result from the local field enhancement of the surface ripples. As the laser shots increase, the LSFL split leads to the formation of nanopillars, and the formation of the nanopillars under the surface LSFL (after ten laser shots) is due to the transition between the LSFL and HSFL with an orientation parallel to the laser polarization. A dip surrounded by annular periodic fringes after 50 laser shots is observed, which is due to the interference of the incident laser field and the reflected laser field on the crater surface. Finally, a direct writing technique for fabrication of nano- gratings is also reported.

Fig. 1. (a) Schematic diagram of the reflection pump-probing setup for the formation of laser- induced periodic surface structures (LIPSS) on As2S3, pump laser: femtosecond laser with the central wavelength of 800 nm, probing laser: CW laser with the central wavelength of 473nm. Experience results are presented by SEM and the upper right corner of each SEM figures are the schematic diagrams of each typical structure. (b) Schematic of sub-wavelength grating structures on As2S3 under the laser velocity speed of 4 mm/s.