With high conversion efficiency and special absorption characteristics, mid-infrared (MIR) lasers have a wide range of applications in gas sensing, biomedicine, remote sensing, and other fields. In recent years, soft glass fibers doped with rare-earth ions have become ideal gain media for MIR laser sources because of their good physical properties, thermal stability and chemical durability, and the ability to observe strong upconversion emission of rare-earth ions in soft glass fibers. Among them, tellurite (based on TeO2) glass is a promising soft glass material with high transparency, high refractive index, high nonlinearity, and low phonon energy. However, tellurite glass fiber-based lasers are not yet commonly used in practical applications, and one of the main reasons is the slow research on the preparation of tellurite glass fiber-based pumping devices. Pump devices mainly include end-pump combiners and side-pump couplers, where a side-pump coupler is a device that couples the pump light from one fiber to the main fiber via the side, which has the advantage of not occupying the end face of the main fiber and uniform pump absorption distribution. The preparation of a tellurite glass fiber side pump coupler is mainly constrained by two aspects: firstly, the pigtailed silica fiber from the pump source must be coupled into the soft glass fiber, and the very different physical properties of the two materials (glass transition temperature and thermal expansion coefficient) make the inter-fiber fusion or lateral coupling complicated; Secondly, the mechanical strength and thermal stability of the soft glass fiber are limited by the need for a reliable heating source for the soft glass.

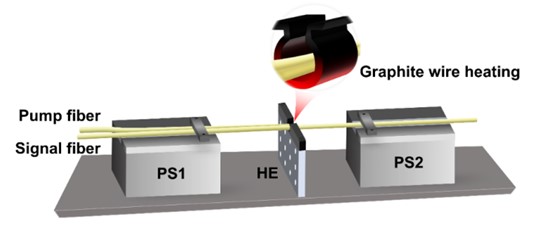

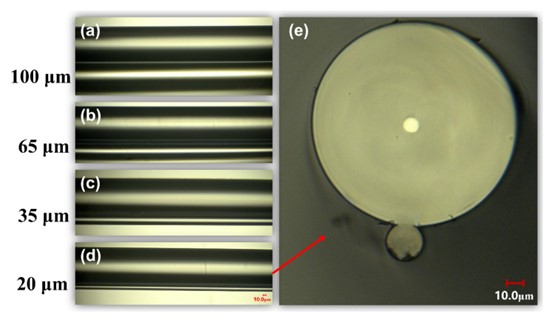

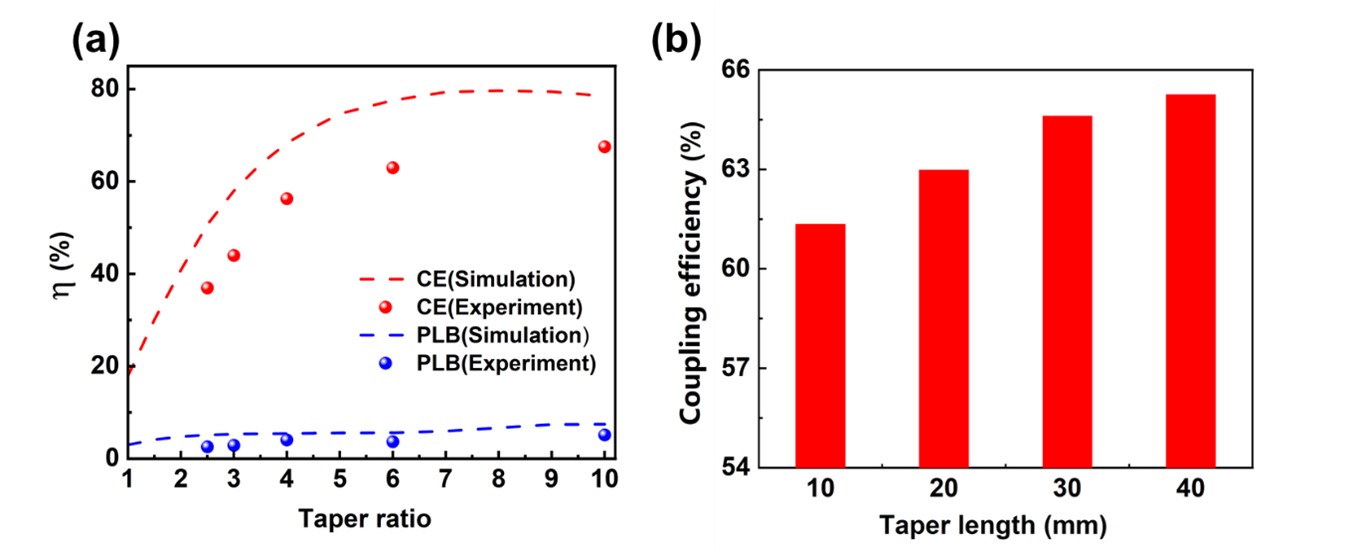

In this work, the coupler was designed based on the ray-tracing method of modeling analysis (shown in Fig. 1), and a single soft glass fiber was used as the heating source in the coupler preparation platform to achieve high-quality tapered and dual fiber fusion coupling (shown in Fig. 2), and a (1+1)×1 laterally pumped coupler based on tellurite glass fiber was prepared for the first time by the fusion taper method. As can be seen from Figs. 3(a)-(e), the fused fiber surface can remain smooth, the core-cladding structure of the signal fiber was not destroyed, and the coupling at lower fusion depth is achieved, which is consistent with the setup in the simulation. The experiments also verified the effects of different taper ratios and taper lengths of the tapered fiber on the coupling efficiency of the side-pump coupler, and compared it with the model simulation results. As shown in Figure 4(a), the coupling efficiency at TR=2.5 is the lowest at 36.97%, while the coupling efficiency reaches 67.52% at TR=10. The coupling efficiency increases with increasing TR and gradually tends to saturate, which is consistent with the simulated trend. As shown in Fig. 4(b), the coupling efficiency increases slowly with the increase of taper length, from 61.35% at TL=10 mm to 65.26% at TL=40 mm. By continuously optimizing the preparation conditions and structural parameters, a side pump coupler with the highest coupling efficiency of 67.52% and insertion loss of 0.52 dB was finally obtained. This work provides a meaningful reference for the preparation of soft glass fiber-based couplers, and the prepared couplers are expected to be applied to mid-infrared fiber lasers or amplifiers.

Fig. 1. (a) Schematic side view of (1 + 1) × 1 side-pumped coupler including important transmission paths and (b) Simulation model applied to ray tracing.

Fig. 2. The fabrication system for side-pump coupler. PS: pulling stage; HE: heating element.

Fig. 3. Different sections of the side-pump coupler when the pump fiber is (a) 100 μm, (b) 65 μm, (c) 35 μm, and (d) 20 μm in the down-taper region through a microscope 500X; (e) (microscope 1000X) cross-sectional view of the coupler at pump fiber of 20 μm.

Fig. 4.(a)Coupling efficiency (red) and percentage of PLB (blue) for different taper ratios (TR). The dashed line and dots are the simulation and experimental results respectively. (b) Coupling efficiency for different taper lengths (TL).

- Pre: 融锥法制备碲酸盐光纤侧面泵浦耦合器研究

- Next: 基于飞秒激光化学腐蚀结合精密模压法制备硫系玻璃微透镜阵列